E450

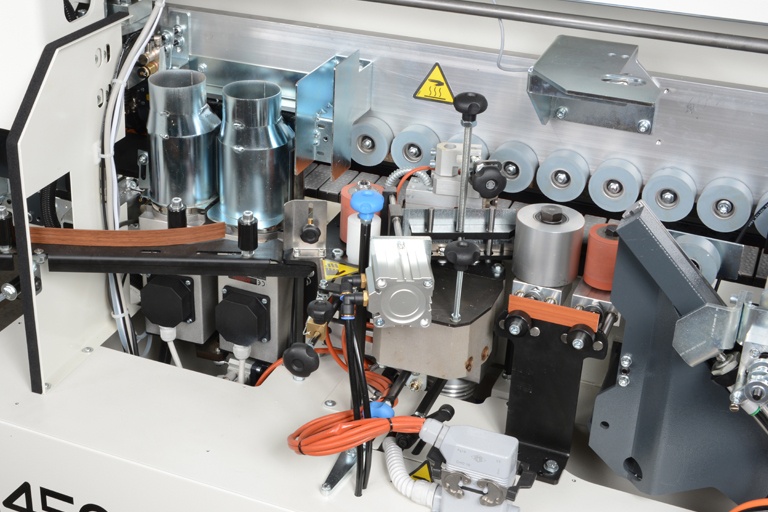

Automatic edge bander with inferior holt- melt glue pot (EVA), chain panel – feeding and pre-milling

Automatic edge bander with inferior holt- melt glue pot (EVA), chain panel – feeding and pre-milling

PRACTICALITY AND PRECISION

Feeding fence

Pre-milling

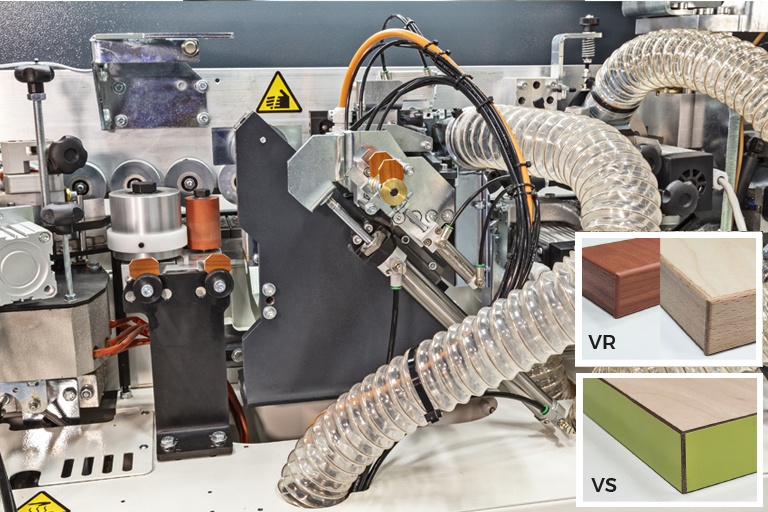

2 processing modes:

“VR1” radius (ABS and PVC thick edges) straight (thin edges and wooden strips)

or

“VS1” bevel (thin edges) straight (thin edges and wooden strips)

MAXIMUM FLEXIBILITY

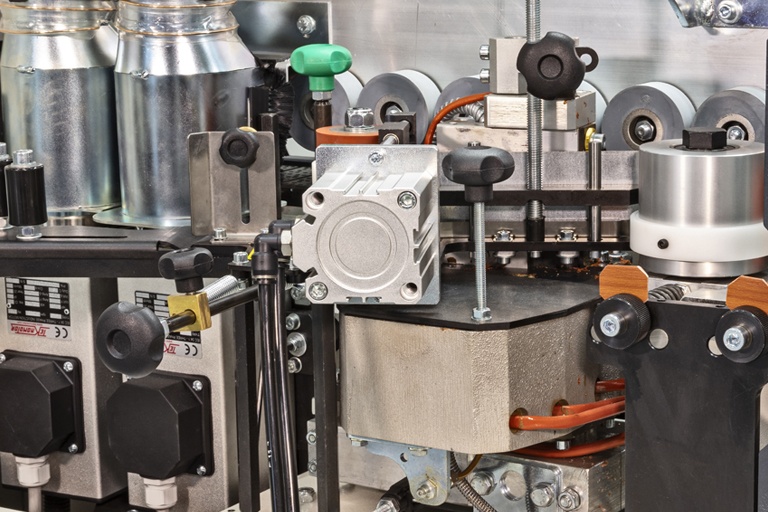

DETAILS THAT MAKE THE DIFFERENCE

TO GUARANTEE THE BEST GLUEING CONDITIONS