E550CRT

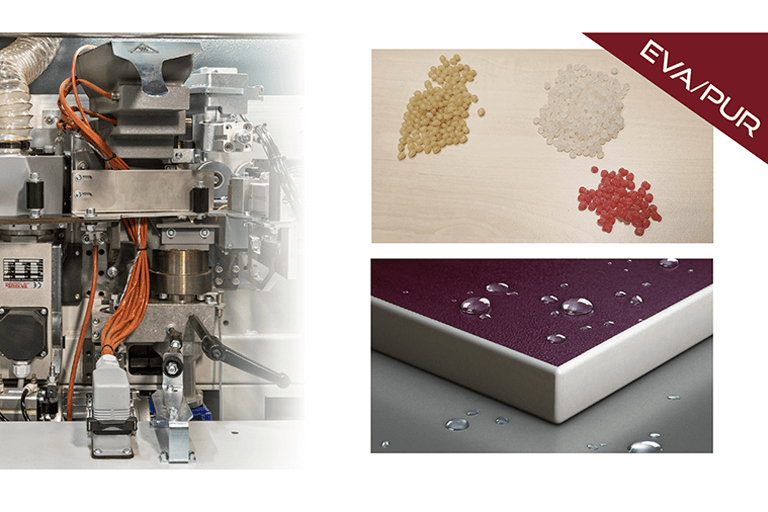

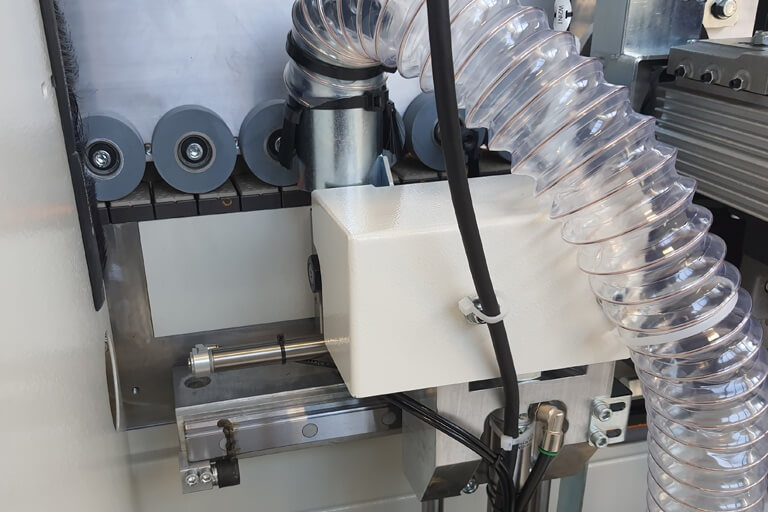

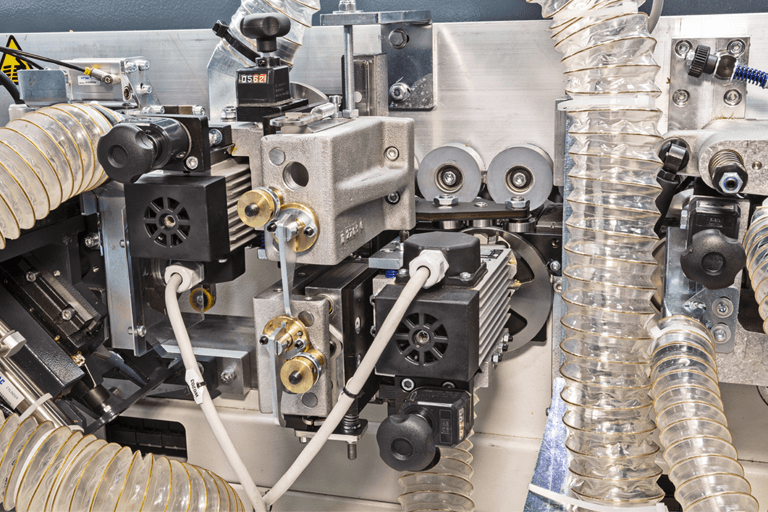

E550CRT – Automatic edge bander with hybrid superior hot melt EVA/PUR polyurethanic (standard), chain panel feeding, pre-milling and corner rounding units

E550CRT – Automatic edge bander with hybrid superior hot melt EVA/PUR polyurethanic (standard), chain panel feeding, pre-milling and corner rounding units

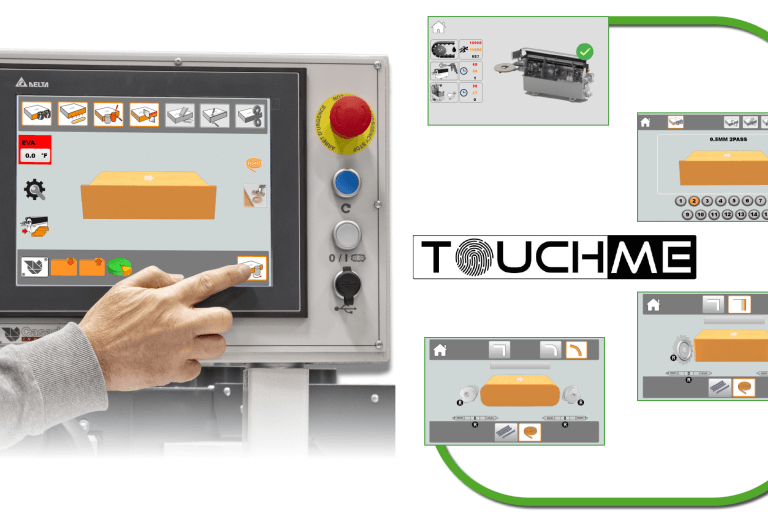

Easy to use, Intuitive and Immediate

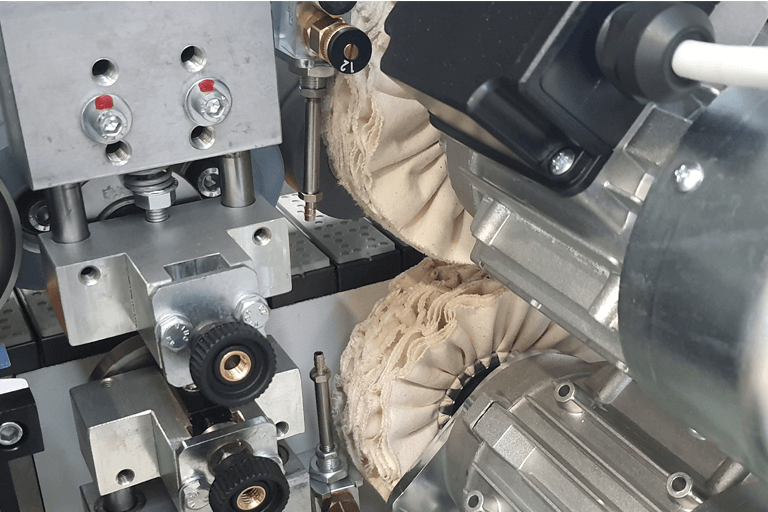

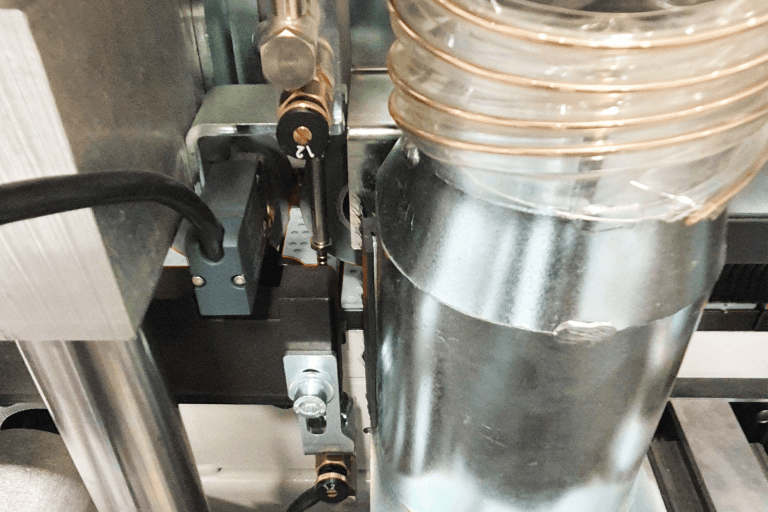

INVISIBLE GLUEING LINE

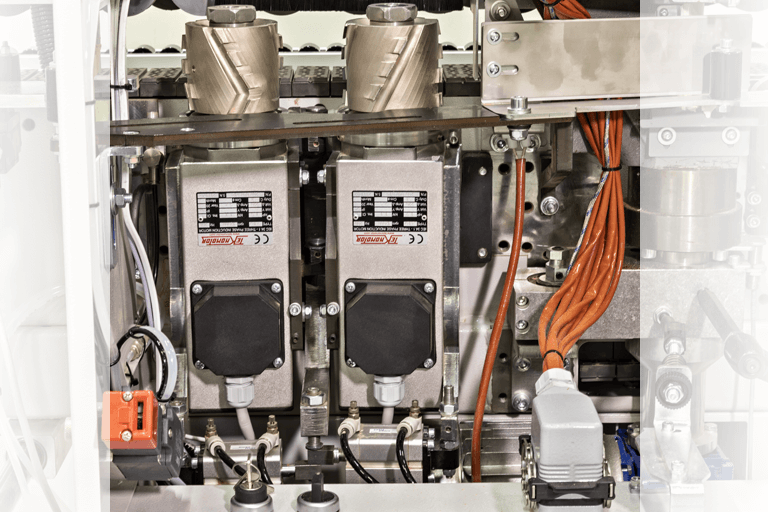

PERFECT GLUEING, QUICK AND PRACTICAL SET-UPS

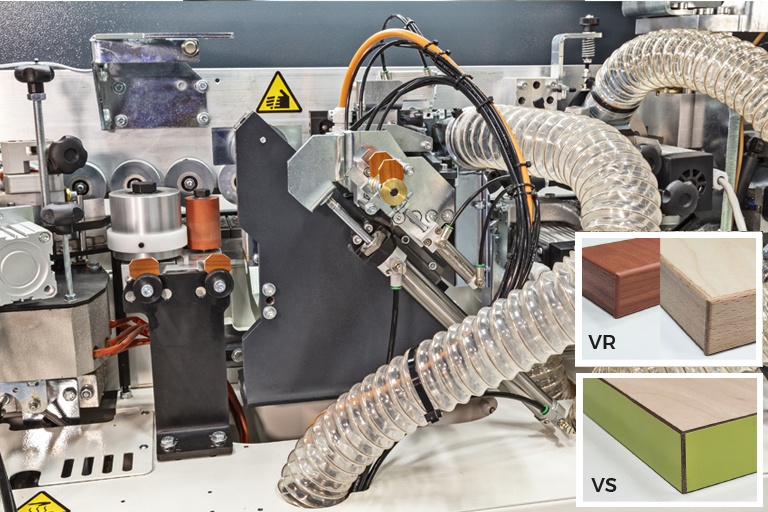

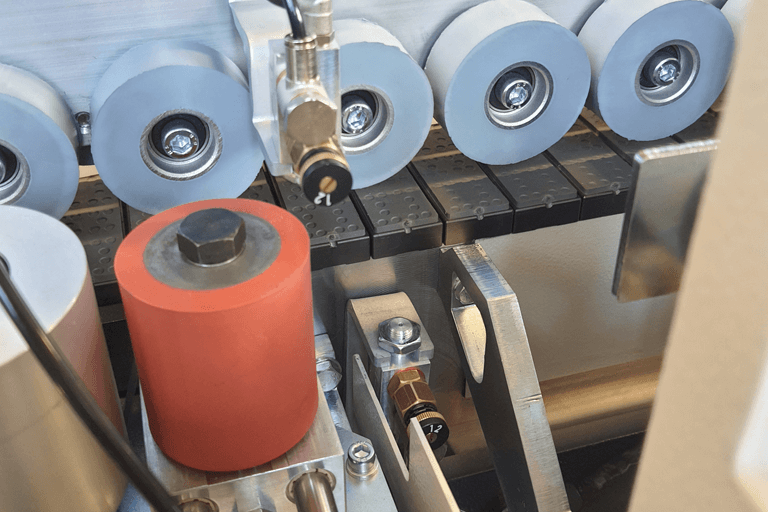

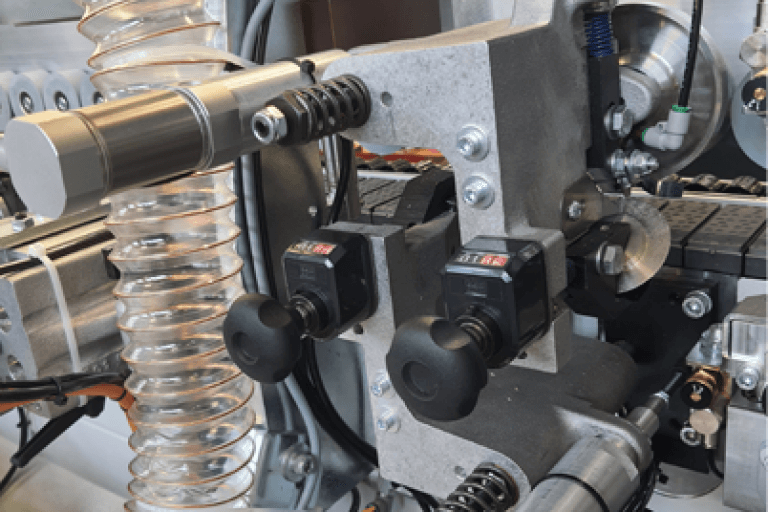

2 processing modes:

“VR1” radius (ABS and PVC thick edges) straight (thin edges and wooden strips)

or

“VS1” bevel (thin edges) straight (thin edges and wooden strips)

PERFORMANCE AND VERSATILITY

FOUR PROCESSES

TO GUARANTEE THE BEST GLUEING CONDITIONS

MIRROR FINISHING

Improves the processing of large panels.

E550T

L 2594mm L 3245mm L 3080mm

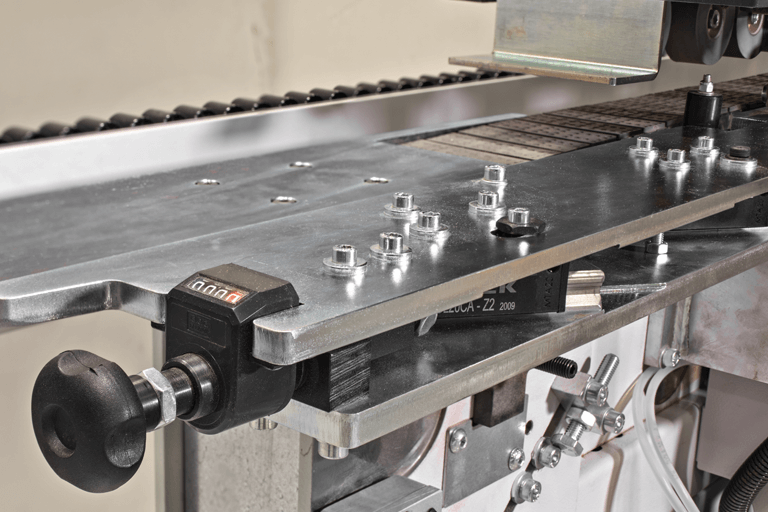

PRACTICALITY AND PRECISION

INSTANT PERFECT CLEANING

PERFECT PLASTIC EDGES EVEN IN BACKLIGHT

REMOVAL OF EXCESS GLUE