Maximum finishing quality

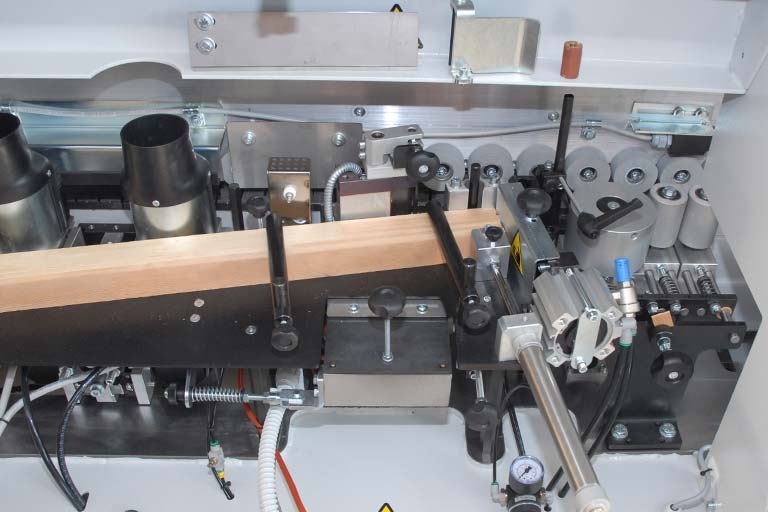

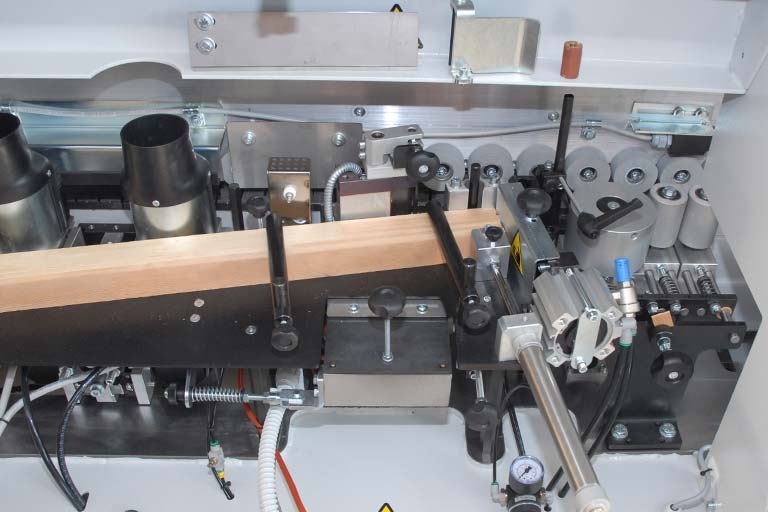

- Chain feeding system

- Pre-milling

- Gluing with polyurethane glue (Opt.)

- Automatic strips storage

- 3 free spaces for finishing units

High performance

- 11 m/min feed speed

- 60 mm panel height

- 3 mm edge coils

- 10 mm edge thickness in strips with automatic loading

Minimum space occupied

- Length 3,7 m K60 PM version

Easy to use

- Easy and intuitive use of machine

- Flush trimmers with multiprofile tool

(thin-R1-R2- strips)

MACHINE DETAILS K60 PM – Stockout

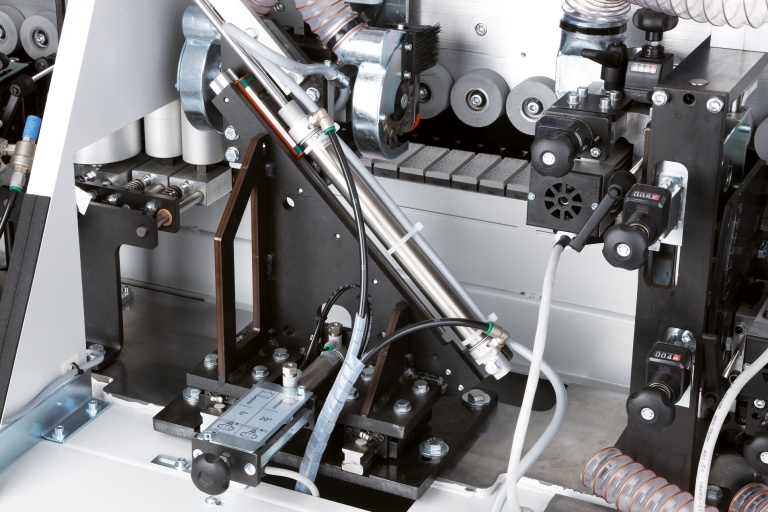

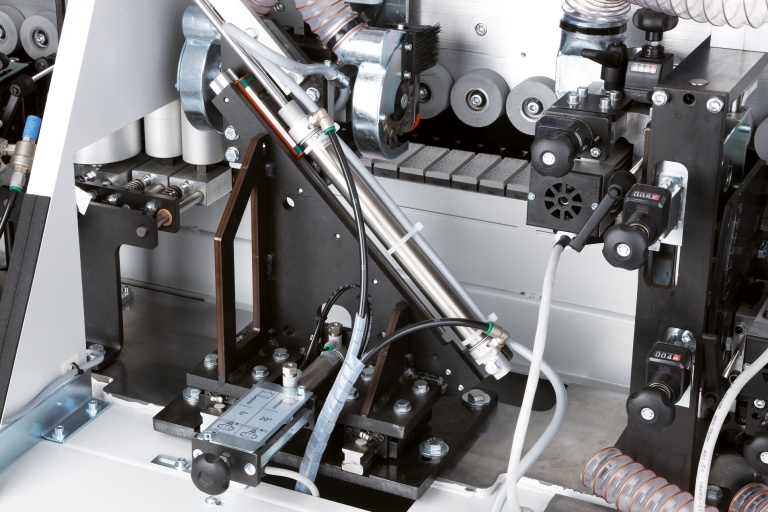

Pre-milling with diamond cutterblocks

- N. 2 diamond cutterblocks at opposite rotation ø 60 mm h 64 mm

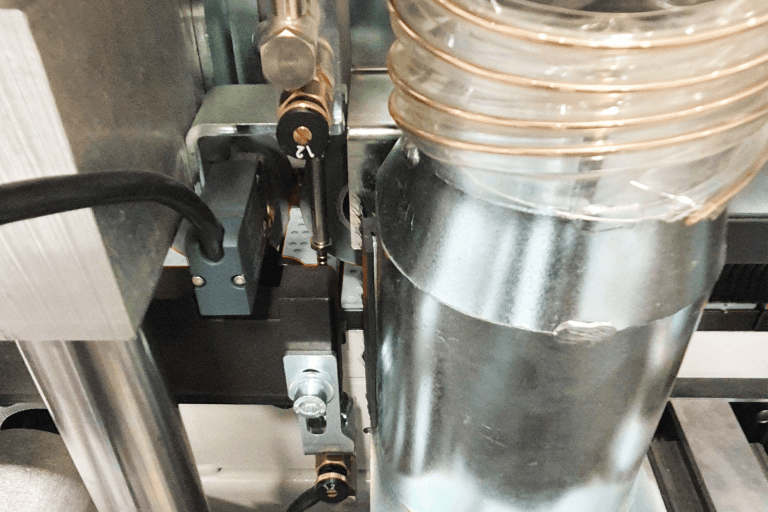

- 2 extractor hoods Ø 80 mm

- Feed guide with micrometric adjustment 0 ÷ 2.0 mm

- HF motors 2 x 1,1kW 12000 rpm

Up to 10 mm wooden strips for panel height up to 60 mm (option available on request)

- Automatic strips loading

- Strip feeding by the pin roller

- Strips storage capacity up to 150 mm

- 1st motorized aluminum pressure roller – ø 110mm

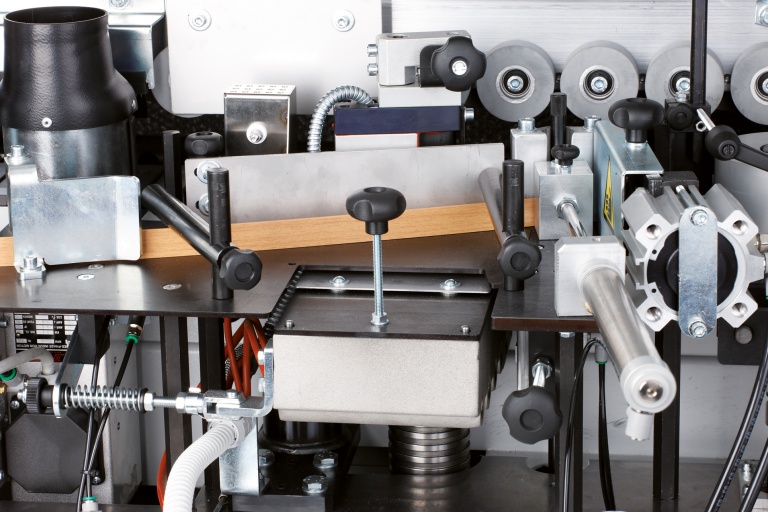

Edge loading surface, with automatic feeding

- Strips storage up to 150 mm capacity

- Strip feeding with needle bearing roller

- 10 mm max strip height

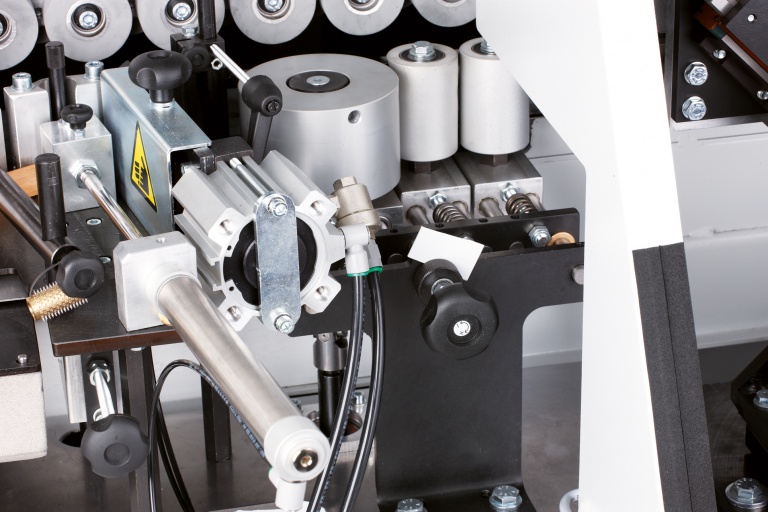

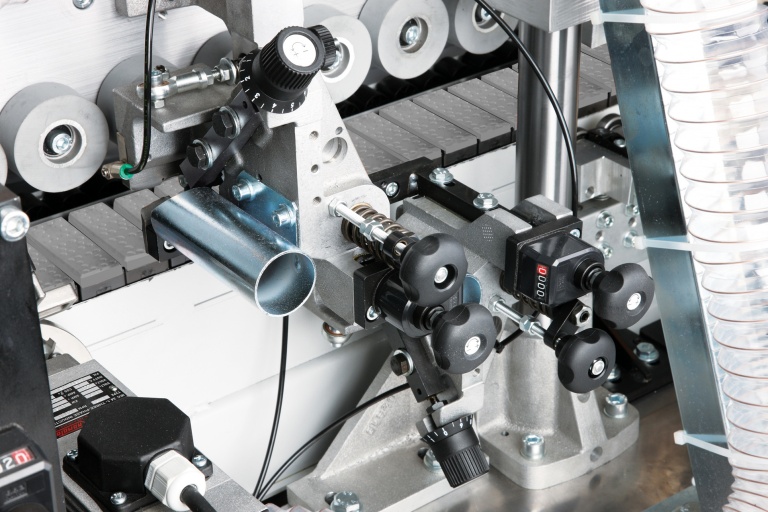

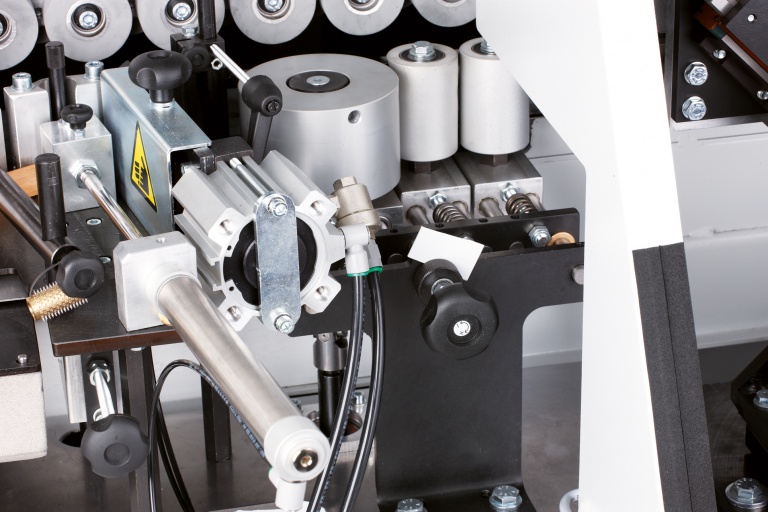

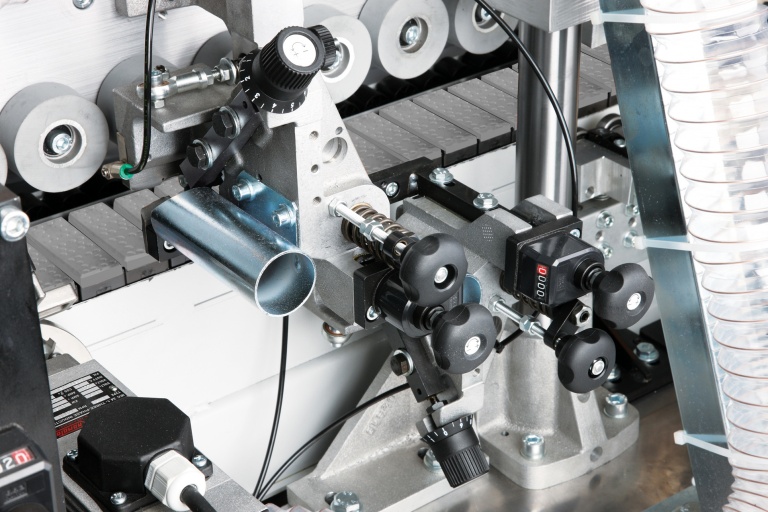

Pressure rollers

- The system “reads” the thickness of the edge, impossible to mistake

- Adjustment with numerical indicators

- Independent pressure adjustment

- 1st motorized aluminum pressure roller – Ø 110 mm

Anti-adherence / release agent spraying unit (Opt.)

INSTANT PERFECT CLEANING

- Spray function controlled by PLC

- 2 sprayers (lower and upper) and liquid tank

Automatic glue drainage cycle. PUR (Opt.)

- Automatic glue drainage cycle.

Equipped with a drip tank of the glue discharged during the drain cycle

- Upon request an additional interchangeable glue pot is available.

- Processing both with PUR and EVA glue

- With PUR glue it is possible to stop machine (up to 4 days) without having to effect any cleaning procedure.

- Automatic cleaning of glue spreader roller

- Glue roller with integrated heating uniform and constant glue temperature

- Granule manual loading (glue pot 0,5 Kg)

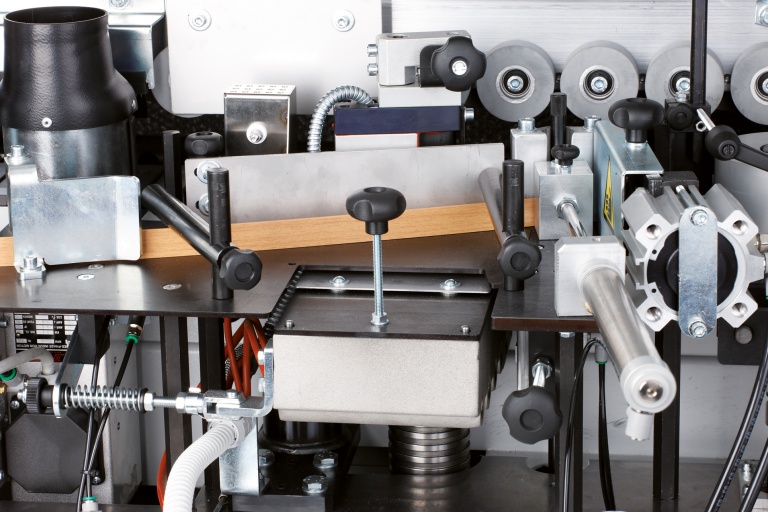

Chain panel feeder with rubber pads

- Feed speed 11 m/min

- Top bar with double row of rubber rollers adjustable in height

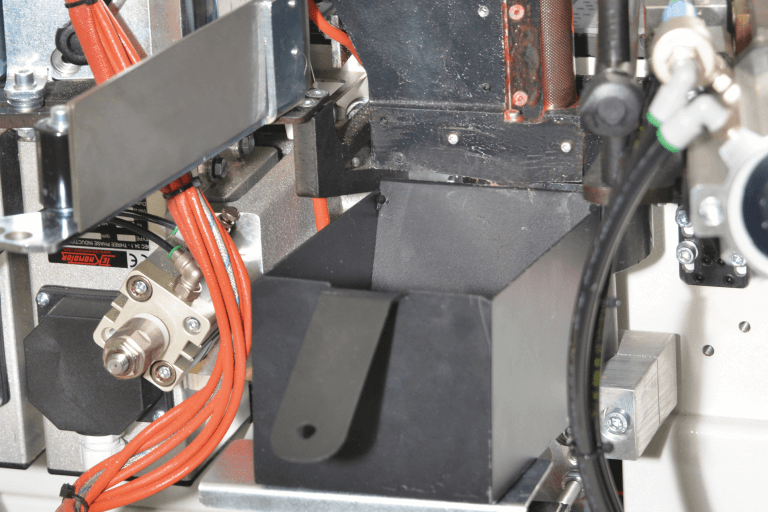

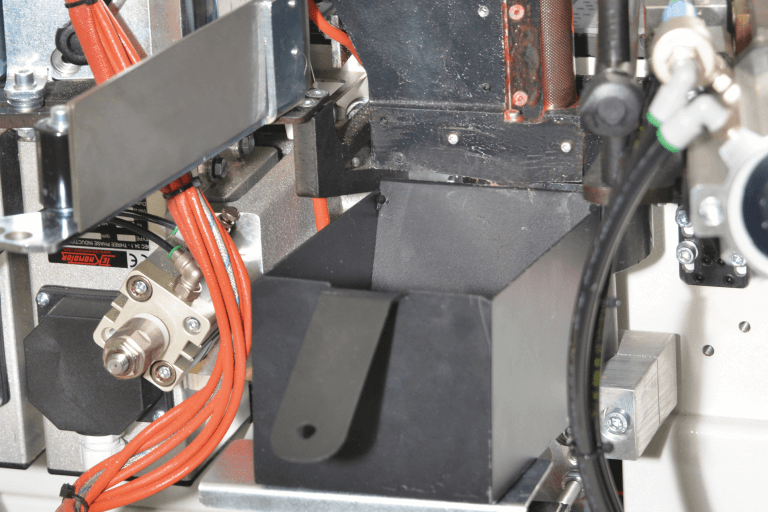

Edge scraping unit (Opz.)

- Widia knives, (radius on request) Numerical indicators

- Blowers for removal of shavings.

- Dust extraction system complete with box to separate and collect scraping shavings.

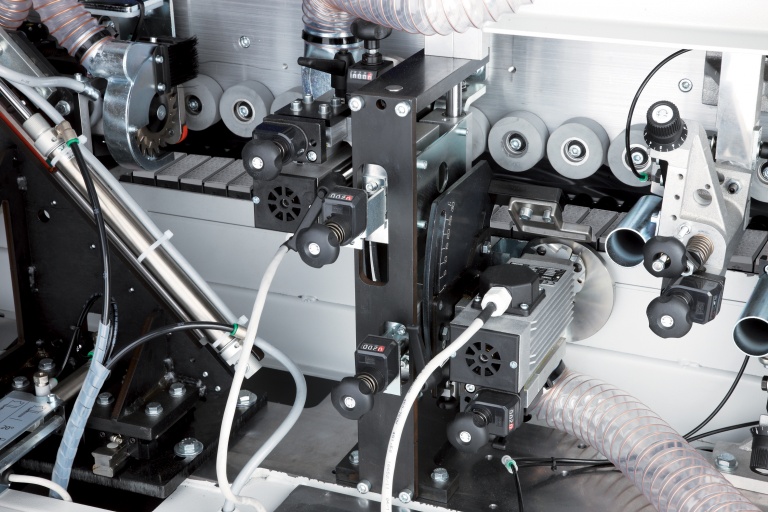

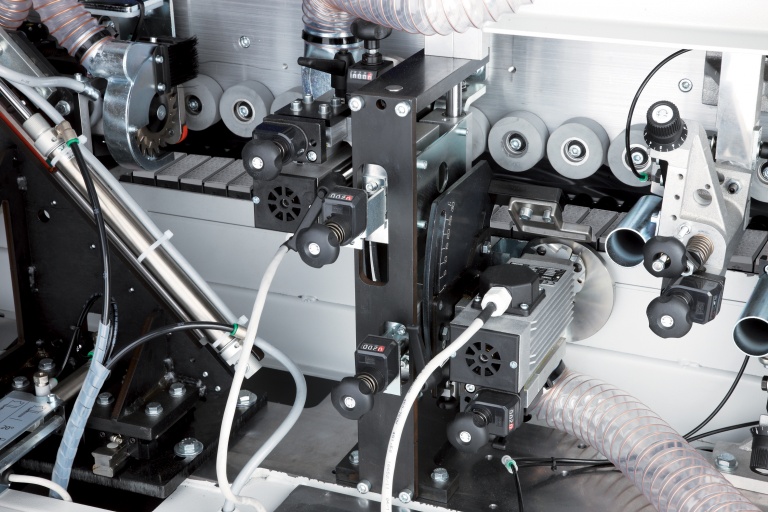

Flush trimmers

- HF motors 200 Hz tiltable up to 25°

- Numerical indicators for adjustments

- Copying discs

- Combined Widia cutters bevelled/radius

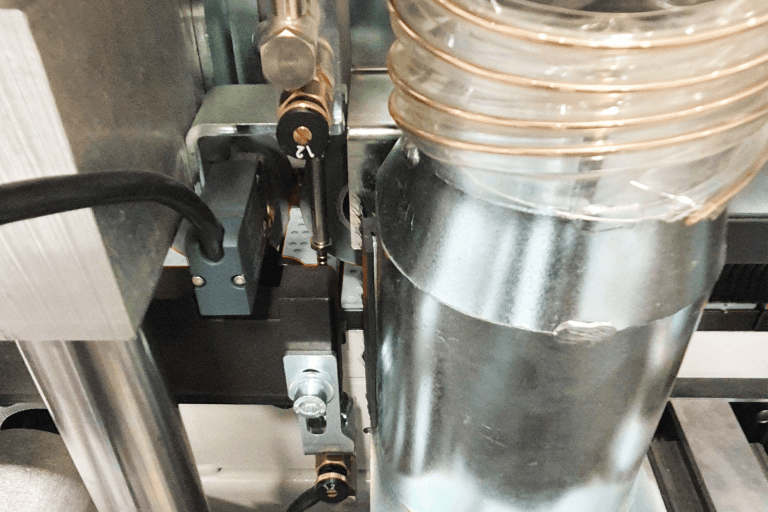

Double blade trimming cut-off

PERFORMANCE AND VERSATILITY

- End trims front and rear excess edge

- Working cycle controlled by PLC

- HF motor 200 Hz

- Dust extraction included

Glueing unit 2 Kg

PERFECT GLUEING, QUICK AND PRACTICAL SET-UPS

- Automatic Stand-by temperature

- Glue pot capacity 2 Kg.

- Teflon coated

- Nr. 7 cartridges 3050 W